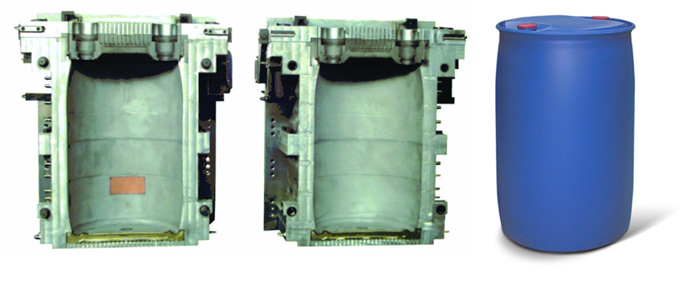

QCM-100-120L

Full-automatic extrusion blow moulding machine

Description:

Configuration

1.)German SEIMENS human-machine interface,easy to control, and the aduanced inverter.

2.) flow and pressure proportional control by Japan YUKEN; Adoting European clamping system,double structure mold parts.

3.)Impoted electronic parts,German SEIMENS welf-functioned and PLC control system.

4.)The range of this quotation list doesn’t include the following items: Wiring, tubing and the material not included in the machine; Material, lubricating oil and hydraulic oil for test run; Transportation costs and insurance.

5.) INSTALLATION AND TEST

The buyer should place the machine to the right position and inform the supplier after the machine reach the buyer’s factory. We will send one engineers to test the machine until it running in normal state. The buyer bears expenses on accommodation, hotel, ticket and medical insurance. you will have to pay $50 per day for the extra days of his stay.

6.) PAYMENT:40% deposit with order by T/T.60% by T/T after inspection

7.) DELIVERY: Delivery 50-60 days from order and deposit.

8.)The seller could train operating man for free if buyer need. (Travel and hotel is by buyer’s expenses.)

9.) VALIDITY

The offer is valid for any order placed within a period of 30 days. Unless otherwise stated all conditions and terms are based on this list.

The offer is offered for the buyer’s need in selecting and not act as the enclosure of contract. The contract is the only standard.

| ITEM | SPECIFICATION | DATA |

| QCM-100 | Max. container capacity | 120L |

| Material | PE | |

| Output | 45ps/hour | |

| Number of die | 1 | |

| No.of station | 1 | |

| Screw diameter(mm) | 100 | |

| Screw L/D ratio(l/d) | 28 | |

| Max.driver(KW) | 120 | |

| Air Pressure(Mpa) | 1 | |

| Plasticising capacity(kg/h) | 320 | |

| Extruder driving power(KW) | 132 | |

| Heating zone | 5 | |

| Heating power (KW) | 32 | |

| Platen size(Lxw) | 1200*1700 | |

| Mold Tickness(mm) | 900*1800 | |

| Clamping force(kn) | 560-880 | |

| Gross Weight(T) | 38 | |

| Machine Size(m) | 7.8*2.5*5.4 |

REMARK

1.) Including the parison control system-MOOG.

2.)German SIEMENS interface, flow and pressure proportional control by Japan YUKEN

3.)German SIEMENS PLC

| Related Products: | ||